A glimpse into Ship Technology and enhancing sustainability of Stern Tube Bearings. Part-II

- Blog ID: TN-BLG-0000023

- Posted On: 24-08-2022, 03:30pm

- Technology: , Ship Technology

- Tags: ,Bearing Tech, Ship technology, Sustainable

- Category: Technical

- Name: Mr. Gandharva Rajendra Jadhav

- Designation: Research Engineer

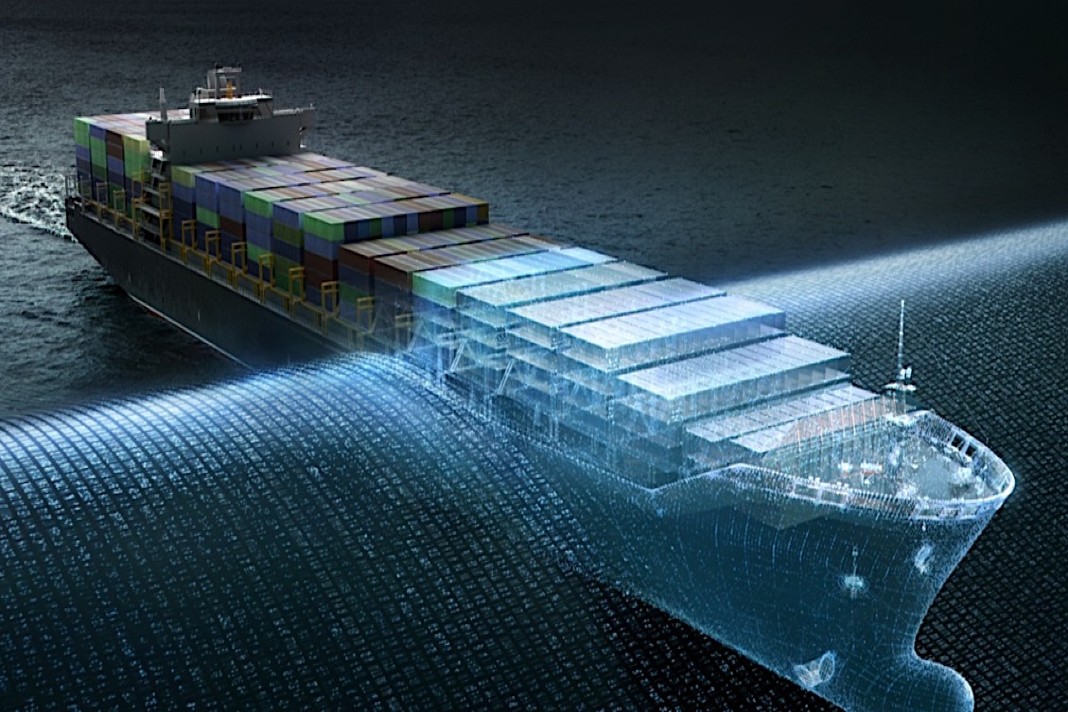

That trade is carried by the roughly 55,000 merchant ships that trade internationally. Whether general cargo, container or tanker, each of these is equipped with one or more propellers that drive the vessel through the water. The propeller in turn is connected to the engine via a shaft, and that shaft is supported by various bearings to keep it rotating smoothly.

These bearings often require grease or oil lubrication. An oil-lubricated stern tube system was introduced in the 1950s to help control the wear life of shaft bearings. One of the system’s components is known as the stern tube bearing, and its main job is to seal the oil-filled stern tube and prevent that oil from going into the sea and causing marine pollution.

Yet accidents still happen.

Fishing nets, misaligned propeller shafts, poorly maintained seals or manufacturing defects can all cause the seal to fail. The resulting loss of oil containment can be costly for the shipowner and lead to fines or even jail time for the crew.

Oil-lubricated stern tube systems were developed ostensibly to control bearing wear life. But what if these systems didn’t need oil at all?

Water-Cooled Bearings

Water-cooled bearings have the advantage of not requiring oil lubrication or EALs (environmentally acceptable lubricants), reducing the pollution risk to zero. While the shaft is spinning at speed the water creates a wedge that completely separates the shaft from the bearing material, bringing the coefficient of friction to under 0.001. This reduces system wear to a negligible amount.

Water also has twice the specific heat of oil. An equal weight of water will absorb twice the heat of oil lubricants, making the cooling properties far superior. By using water as a lubricant, contamination seals are not required. If seals are not required, pumps and tanks may not be necessary. This leads to a simpler shaft-bearing system and immediate cost savings in the build phase.

Stern tube bearings are designed with a series of lands and grooves, running longitudinally. When a contaminant such as sand or grit enters the system, the water will wash it into a groove where it is flushed out. Due to the material construction of this style of bearing, it avoids scoring the propeller shaft, unlike a metal bearing, which has no give.

Further, a greased shaft will trap contaminants, essentially turning it into a lapping compound. This will continuously wear the shaft with every rotation.

Water-cooled bearings have been developed using the most modern technology available and one of the oldest sustainable resources known to man.

Composite Bearings

Thordon Bearings, a Thompson Gordon company, is an Ontario-based manufacturer specializing in the production of oil-and-grease-free bearings and seals. The company uses a proprietary, grease-free, water-lubricated polymer material. This low-coefficient bearing material helps to reduce shaft/bearing friction and eliminates stick slip.

Thordon recently produced the largest rudder bearing ever manufactured – in twenty-four hours, no less!

A containership drydocked in Dubai was found to have rudder bearing clearances at the limit. With the end of the maintenance period fast approaching, the owner needed to decide whether to return to drydock or replace the existing metal bearing with Thordon’s water-lubricated technology. Thordon’s local partner, Ocean Power International, assured the shipyard it could deliver the bearing on time.

With only a rudder stock drawing to reference, Thordon’s Burlington, Ontario-based team cast an oversized piece with an ample safety margin. The finished piece measured 1,250 mm x 1,050 mm x 1,350 mm and weighed 2,500 lbs. While the largest bearing ever delivered, it was still seven times lighter than a comparable bronze bearing and light enough that it was loaded onto a commercial airliner that night.

Twenty-four hours later the bearing arrived in Dubai where the local team completed final machining to the exact specifications. The piece was then supercooled using liquid nitrogen, causing the outer diameter to shrink by 21.93 mm and allowing the bearing to be easily fitted in place.

The resulting installation has a higher abrasion resistance than the bronze bearing it replaced with double the expected working life.

Multi-Vessel Contract

The advantages of water-cooled bearings paired with Thordon’s fast delivery time have led to a multi-vessel agreement with Maritime Partners, the world’s largest operator of inland vessels.

Twelve twin-screw push boats are scheduled to be delivered from Louisiana-based FMT Shipyard with equipment that includes RiverTough tailshaft bearings, ThorPlas-Blue rudder bearings with Pucker Seals, ThorPlas-Blue steering linkage bushings, SXL thrust washers and TG100 tailshaft seals.

Operating one of the most modern, new and environmentally efficient fleets across the U.S. inland river network, Maritime Partners went all-in with Thordon’s water-cooled solutions to ensure reliable operation and zero pollution risk.

- Like

- Share

Comments (4 Comments)